Unleashing the Potential of Robotics Today

As NOWfab stand at the cusp of a new era in robotics, it is our duty to expedite the development and integration of advanced robotic technologies into various sectors. By harnessing the power of innovation, we are dedicated to driving the robotics industry forward and unlocking new potential for growth and efficiency.

- Custom Solutions for All Industries

- Accessible Parts at Competitive Rates

- Quality Without Compromise

NOWfab's Robotic Product Launch Framework

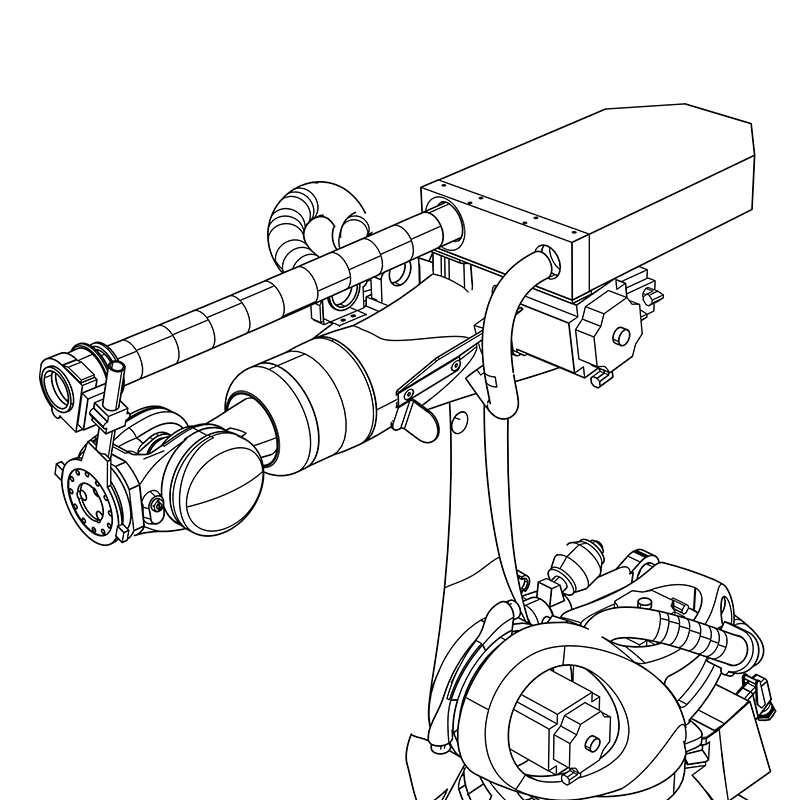

Swift 3D Prototyping with Diverse Technologies

NOWfab employs an array of cutting-edge 3D printing technologies to offer swift prototyping services for robotics projects. Our capabilities range from intricate detail fabrication to the assembly of complex mechanical components, ensuring that your prototypes are not only visually accurate but also practically functional.

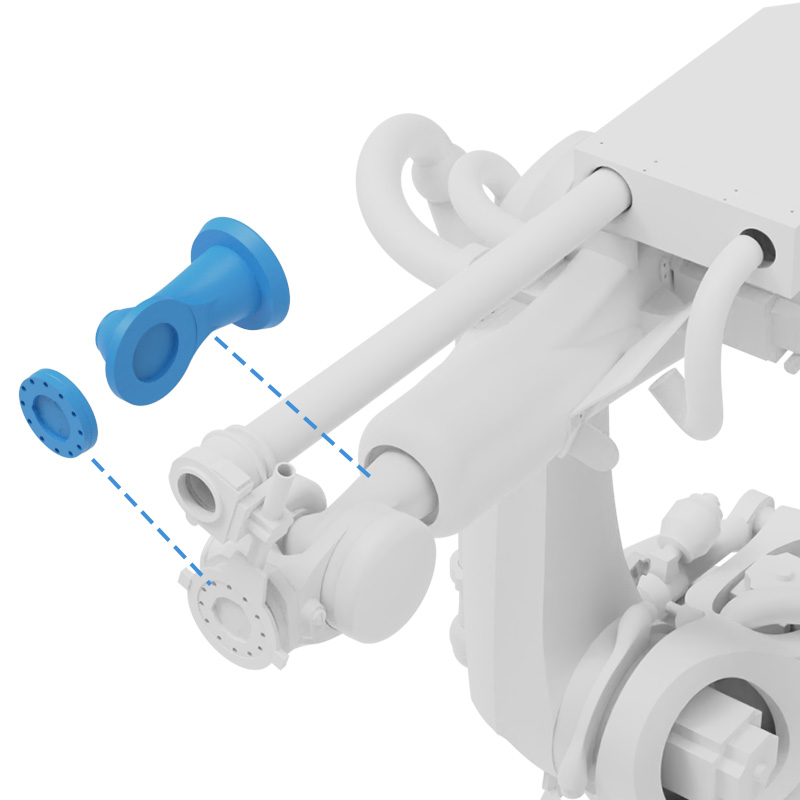

Urethane Casting for Resilient Prototypes

For robotics prototypes that necessitate enhanced durability and a refined finish, NOWfab's urethane casting services are the premier choice. This method produces prototypes with superior strength and a precise form, ideal for rigorous testing and validation processes.

Agile Design Iteration and Adaptability

In the dynamic field of robotics, adaptability is key. NOWfab's NPI Solutions facilitate an agile design iteration process, allowing for swift modifications and improvements based on testing feedback. This iterative approach ensures that your final product is finely tuned to meet your specifications and exceed performance expectations.

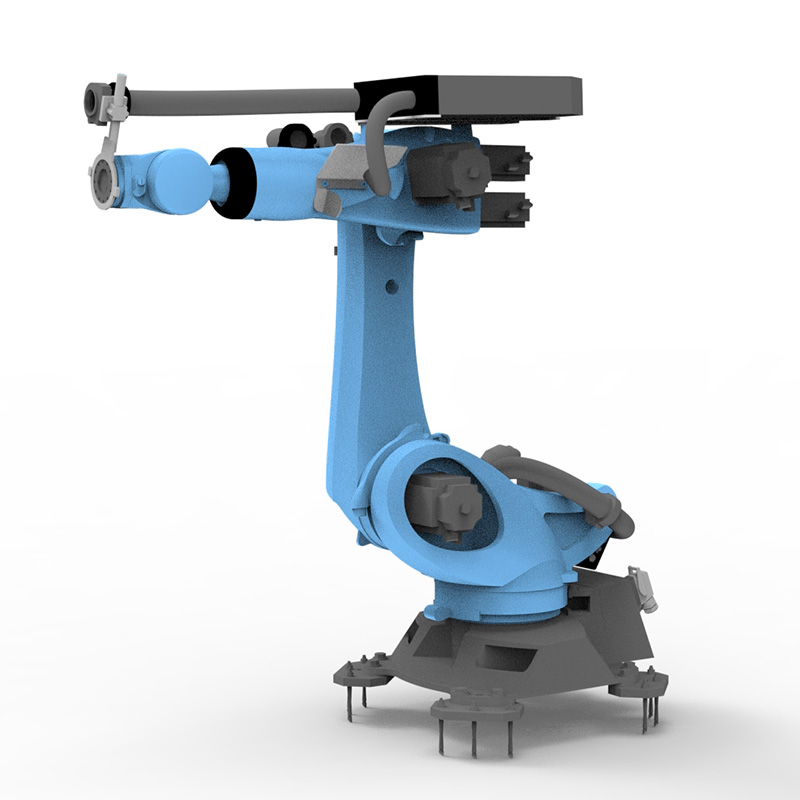

Smooth Transition to Manufacturing

Post-prototyping, NOWfab ensures a smooth transition from prototype to production. Our services are designed to maintain continuity, applying the insights gained during prototyping to the manufacturing phase. This results in a seamless scale-up process, delivering a product that is not only reliable but also ready for market deployment.

Why Robotics Companies Choose NOWfab

Accelerated Development Cycle

NOWfab’s expedited processes slash development time by 30% on average, fast-tracking robotics products from concept to market without compromising on quality or precision.

Unfaltering 99.9% Quality Rate

NOWfab’s meticulous processes ensure near-perfect quality standards, with a pass rate of 99.9%, demonstrating exceptional reliability in every robotics component manufactured.

Precision Tolerances Up to ±0.05mm

NOWfab adheres to stringent standards, offering robotics companies tolerances as precise as ±0.05mm. This meticulous accuracy ensures seamless assembly and flawless functionality, critical for high-performance robotics systems.

Endorsed by Top Robotics Engineers

Come With Us on a Journey to Innovate Better and Faster