CNC Machining Service

Harness state-of-the-art equipment and expertise to turn designs into reality, from prototype to production. Experience unmatched quality and rapid turnaround for all your CNC needs.

- Delivery Nationwide as Fast as 24 Hours

- Competitive Pricing Model

- Superior Quality Assurance

Our CNC Machining Processes

CNC Milling

Utilizes rotary cutters to remove material from a workpiece. operate from simple cuts to complex shapes and surface contours.

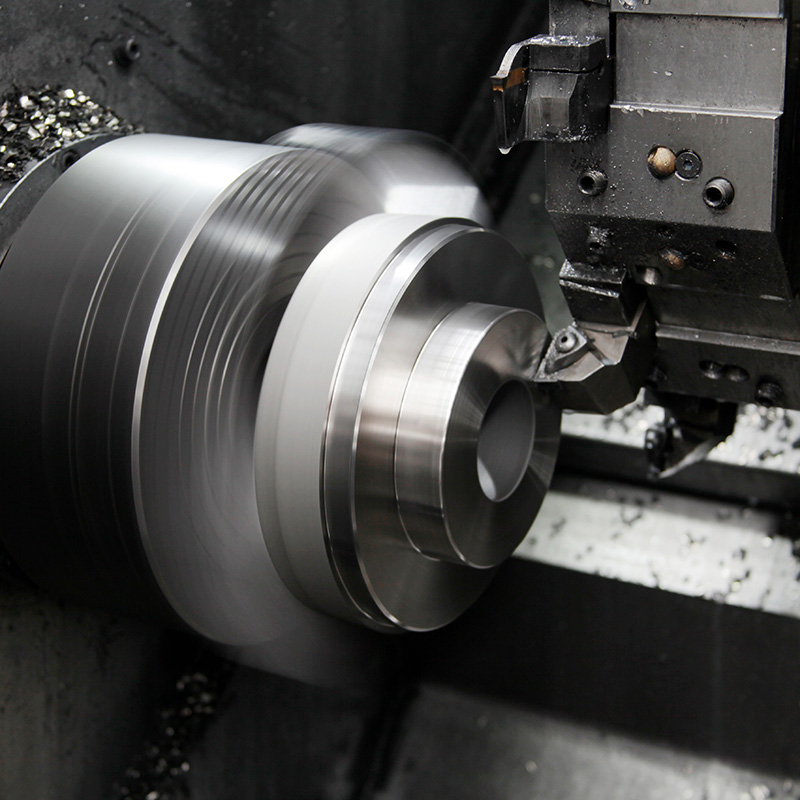

CNC Turning

Material is rotated as a cutting tool is traversed along two axes of motion to produce cylindrical cuts with precise dimensions.

CNC Drilling

Produces cylindrical holes in a workpiece, can include simple straight holes to complex routing operations for larger openings.

CNC Grinding

Uses abrasives to remove material and finish surfaces with high precision, suitable for achieving fine tolerances and surface finishes.

5-Axis Machining

Provides multi-directional movement of the tool and workpiece. Allows for complex shapes, undercuts, and deep-hole drilling.

EDM

Uses electrical discharges or sparks to form a metal workpiece, excellent for complex or hard materials.

CNC Machining Materials

Plastic Material

ABS

ABS (Acrylonitrile Butadiene Styrene):

Widely used due to its versatility and ease of machining.

PC

Polycarbonate (PC):

Known for its strength and transparency, popular in many applications.

PP

Polypropylene (PP):

Lightweight, chemically resistant. Good impact resistance, heat tolerant.

PA

Nylon (PA):

High-strength, wear-resistant. Chemically resilient, used in mechanical parts.

POM

Acetal (POM):

High strength, rigid. Excellent wear resistance. Stable in size, chemically resistant.

PVC

PVC (Polyvinyl Chloride):

Durable, chemically resistant. Flexible or rigid, common in construction.

PSU

Polysulfone (PSU):

High-performance, heat-resistant. Strong, used in medical and electronics.

PMMA

Acrylic (PMMA):

Transparent, UV-resistant. Lightweight, ideal for signage and lighting.

UHMWPE

UHMWPE (Ultra-High Molecular Weight Polyethylene):

Extremely tough, low friction. High abrasion resistance, used in sliding parts.

PTFE

PTFE (Teflon):

Non-stick, low friction. Chemically inert, excellent for seals and bearings.

Metal Material

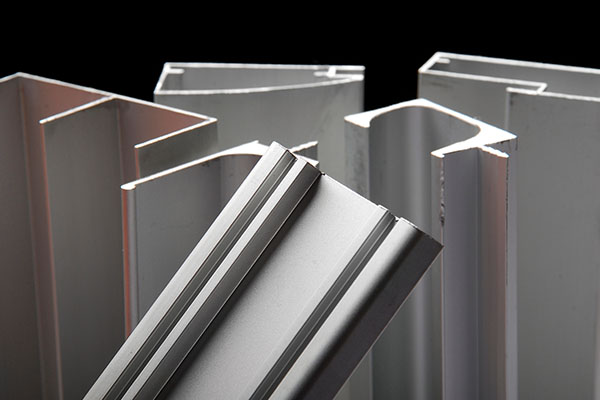

Aluminum Alloys

Lightweight and strong, aluminum alloys are widely used in aerospace, automotive, and electronics industries due to their excellent machinability and corrosion resistance.

Steel (Carbon and Alloy)

Known for its high tensile strength and durability, steel is a go-to material for heavy-duty applications, including construction, automotive parts, and tools.

Stainless Steel

Resistant to corrosion and staining, stainless steel is a popular choice for applications that require high strength and cleanliness, such as food processing equipment and surgical instruments.

Copper Alloys

Copper and its alloys are valued for their excellent electrical and thermal conductivity, making them ideal for electrical components and heat exchangers.

Brass

A copper-zinc alloy, brass is often used for its machinability and resistance to corrosion.

It's common in decorative applications and fittings.

Bronze

Another copper alloy, bronze is known for its strength and resistance to wear.

It's frequently used in bearings and marine applications.

Titanium

Despite its high cost, titanium is favored for its high strength-to-weight ratio and corrosion resistance, particularly in aerospace and biomedical applications.

Inconel

A group of nickel-based superalloys, Inconel is used in extreme environments due to its high resistance to heat and corrosion.

Maraging Steel

Known for its high strength and hardness, maraging steel is used in applications requiring precision and strength, such as aerospace fasteners.

Tool Steel

Used for making cutting tools and dies, tool steel is chosen for its toughness and ability to hold a sharp edge.

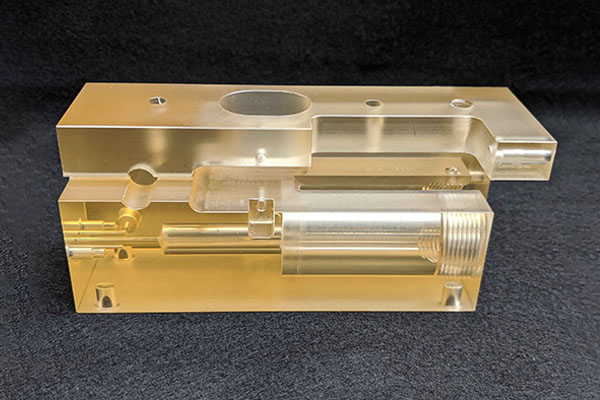

CNC Machining Parts Made by NOWfab

Explore Our Success Stories: Overcoming Customer Challenges

Imagine trying to fit a square peg into a round hole – that was us, struggling to meet the precise needs of our latest medical device. Then came NOWfab, and it’s like they handed us the perfect circle. Their CNC machining service wasn’t just about getting the job done; it was about understanding the heartbeat of our project. The NOWfab team walked us through every step, helping us select the right materials and refine our designs to meet rigorous medical standards. Their commitment turned our challenges into triumphs, fast-forwarding our development and enhancing our product quality.With NOWfab, it felt like they were part of our team, dedicated to bringing our vision to life.

When we dreamt up our new line of eco-friendly outdoor gear, we knew we wanted to make a splash in the market. Speed and innovation were our mantras, but we hit a wall with the prototyping phase. That’s when NOWfab stepped in, turning our hurdles into springboards. Their CNC machining magic turned our concepts into tangible, high-quality prototypes, allowing us to test and refine with agility. Their knack for working with sustainable materials without sacrificing design or durability was nothing short of remarkable. NOWfab didn’t just help us cross the finish line; they made sure we did it with a product that set new standards for quality and sustainability.

Developing service robots that are both strong and lightweight felt like searching for a unicorn. That was until we partnered with NOWfab. Their expertise in CNC machining was exactly what we needed. They were more than service providers; they were collaborators who brought our ideas to life with precision and ingenuity. With their help, we experimented with designs and materials that were previously just sketches on a drawing board. NOWfab’s contributions went beyond machining; they provided insights that improved our robots’ functionality and reliability. Working with them was a journey of overcoming design challenges and pushing the boundaries of robotics innovation.

Come With Us on a Journey to Innovate Better and Faster