3D Printing Service

NOWfab offers instant quotes, competitive pricing, and rapid delivery for top-quality 3D printed parts. Regardless of your project phase, upload your designs to receive an instant quote and get parts by as soon as the next day.

- ISO 9001 Certified

- Parts Delivered as Fast as 24 Hours

- Quality Without Compromise

Our 3D Printing Processes

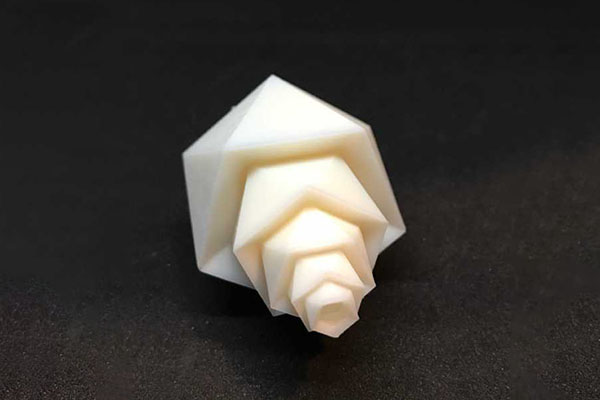

SLA

Precision & complex geometries and smooth finishes.

SLS

Robust parts, ideal for functional applications.

SLM

Strong, dense metal parts for demanding applications.

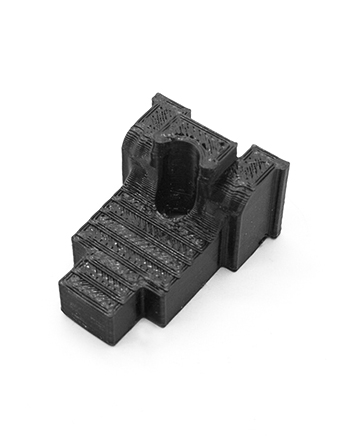

FDM

Strength and flexibility for your prototypes and parts.

MJF

Speed and quality for prototypes to end-use parts.

DLP

High-resolution for intricate designs and rapid prototyping.

3D Printing Materials

Process: SLA

General-Purpose Resin

A versatile resin that serves as a good starting point for many applications. It offers a balance of print quality, detail resolution, and cost-effectiveness.

High-Resolution Resin

Designed for prints that require finer details and smoother surfaces. It's ideal for intricate models and delicate prototypes where surface finish is crucial.

Rigid Resin

Provides increased stiffness and durability, making it suitable for functional prototypes and parts that need to maintain their shape under stress or load.

Flexible Resin

Offers a rubber-like flexibility, perfect for creating flexible parts, such as grips, seals, and elastic components that require a degree of giv.

Dental Resin

Specifically formulated for dental applications, this biocompatible resin is ideal for creating dental models, prosthetics, and orthodontic appliances.

Castable Resin

Designed for investment casting, this resin can be burned out of a mold, leaving a cavity ready for metal to be poured in, suitable for creating metal parts.

Metal-Filled Resin

Infused with metal particles, these resins mimic the appearance and feel of metal, providing a more premium look and feel for prototypes and decorative parts.

Heat-Resistant Resin

Designed to withstand higher temperatures, these resins are suitable for parts that will be exposed to elevated temperatures or used in high-heat applications.

Process: SLS

Nylon

A strong and flexible material that is widely used in SLS printing. It has good mechanical properties and is suitable for functional prototypes and end-use parts.

Polyamide (PA)

High resistance to chemicals and wear. It's often used for functional testing and manufacturing of complex parts.

Carbon-Fiber-Reinforced Nylon

With the addition of carbon fibers, this nylon-based material offers increased stiffness and strength. It's used for parts that need to withstand high loads and stresses.

Aluminum Alloy

Aluminum alloy powders can be sintered using SLS to create parts with a high strength-to-weight ratio. It's suitable for aerospace, automotive, and engineering applications.

Titanium

Titanium is a high-strength, low-density metal that provides excellent corrosion resistance. It's used in applications that require high strength and durability, such as medical implants and aerospace components.

Stainless Steel

Stainless steel is corrosion-resistant and has high strength. It's used for functional parts that need to be durable and resistant to harsh environments.

Metal-Filled Thermoplastics

These materials combine the properties of thermoplastics with metal fillers to provide increased strength and rigidity. They are used for parts that need to mimic the feel and durability of metal.

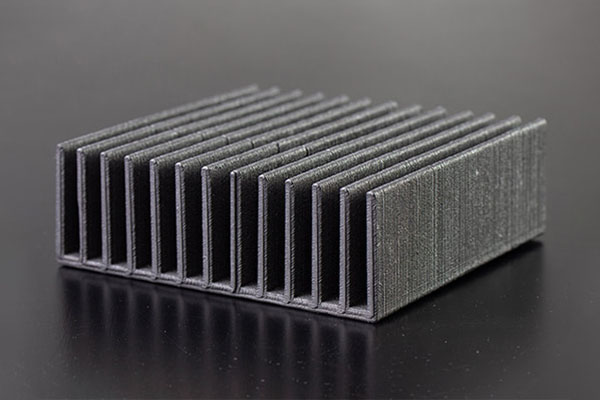

Process: SLM

Aluminum Alloy

Aluminum alloys offer a combination of light weight, strength, and good thermal conductivity. They are used in automotive, aerospace, and electronics industries.

Titanium

Titanium is known for its high strength-to-weight ratio, excellent corrosion resistance, and biocompatibility. It is commonly used in aerospace, medical, and high-performance applications.

Stainless Steel

Stainless steel is durable and resistant to corrosion, making it ideal for harsh environments and applications requiring high strength and durability.

Nickel-Based Superalloys

Excellent high-temperature strength and resistance to oxidation, making them suitable for aerospace and power generation applications.

Cobalt-Chromium Alloy

Cobalt-chromium alloys are known for their wear resistance and biocompatibility, often used in medical implants and dental prosthetics.

Maraging Steel

Maraging steel offers high strength and toughness through a precipitation hardening process, used in applications requiring high strength and precision.

Tungsten

Tungsten is a dense and highly metal with excellent heat resistance, used in applications that require materials to withstand high temperatures and abrasion.

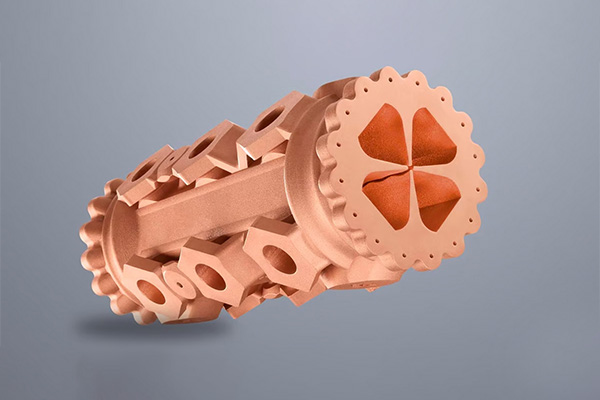

Copper

Copper is known for its excellent electrical and thermal conductivity, often used in electrical components and heat exchangers.

Process: FDM

Polylactic Acid

PLA is a biodegradable thermoplastic derived from renewable resources like cornstarch. It is easy to print with, has a low shrinkage rate, and is commonly used for prototypes, models, and educational purposes.

ABS

ABS is a strong and durable plastic with good impact resistance. It is widely used in the production of functional prototypes, consumer goods, and parts that require rigidity and heat resistance.

Polycarbonate (PC)

Polycarbonate is a high-strength, transparent material with excellent impact resistance and dimensional stability. It is suitable for applications that require high mechanical strength and a clear, glossy finish.

Nylon

Nylon is a strong and flexible material with good wear resistance and chemical stability. It is often used for functional parts, such as gears and mechanical components, that require durability and flexibility.

Polyethylene (PE)

Polyethylene is a flexible material with good chemical resistance and low friction. It is suitable for applications that require a soft, rubber-like feel and resistance to environmental factors.

Polypropylene (PP)

Polypropylene is a lightweight, chemically resistant plastic with good strength and flexibility. It is often used for packaging and parts that need to withstand harsh chemicals or frequent washing.

TPU

TPU is a flexible, elastic material with excellent abrasion and impact resistance. It is ideal for printing flexible parts, such as seals, gaskets, and wearable items.

Metal-Filled Filaments

These filaments are reinforced with metal particles, such as bronze or copper, to provide a metallic appearance and improved mechanical properties. They are used for parts that require a metallic look and added strength.

Process: MJF

Nylon 12

Nylon 12 is a strong and durable material with good chemical resistance and low moisture absorption. It is often used for functional prototypes and end-use parts that require high strength and precision.

TPU 92A

TPU 92A is a flexible material with excellent elasticity and impact resistance. It is suitable for creating soft grips, cushions, and parts that need to withstand repeated stress without breaking.

ABS-M30

ABS-M30 is a modified version of ABS with improved mechanical properties, including better heat resistance and impact strength. It is used for parts that require rigidity and durability.

PA 12

Polyamide 12, often referred to as PA 12, is known for its high strength, toughness, and resistance to wear and chemicals. It is ideal for manufacturing high-performance parts with smooth surfaces.

HSS

HSS is a metal material used in MJF that offers high hardness and wear resistance, making it suitable for creating cutting tools, molds, and parts that need to maintain sharp edges at high speeds.

PP

Cast polypropylene is a variant of PP that offers improved isotropy and surface quality. It is used for parts that require a balance of strength, stiffness, and chemical resistance.

Aluminum Alloy

Aluminum alloy materials in MJF offer a high strength-to-weight ratio and good thermal conductivity. They are suitable for aerospace, automotive, and engineering applications.

Titanium

Titanium is a strong, lightweight, and corrosion-resistant material. It is used in applications that require high strength and durability, such as medical implants and aerospace components.

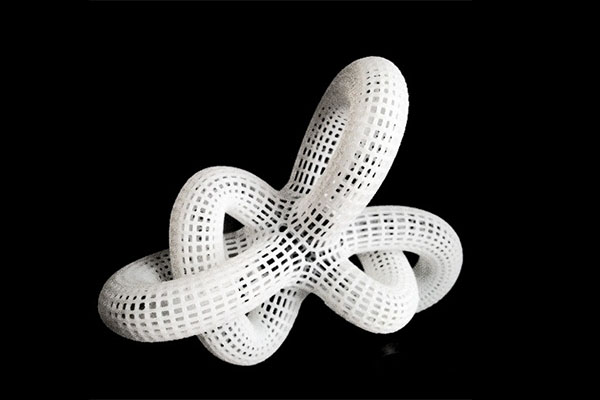

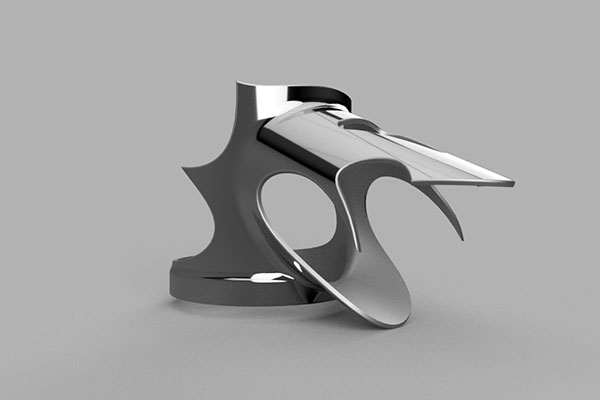

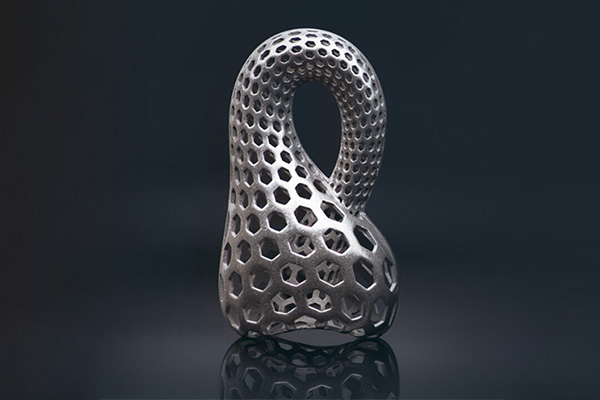

3D Printed Parts Made by NOWfab

Explore Our Success Stories: Overcoming Customer Challenges

NOWfab tackled our most challenging design specifications with their advanced SLA 3D printing solutions. Their meticulous attention to detail and ability to accurately reproduce complex designs were unparalleled. Facing a tight deadline, their team demonstrated exceptional dedication, working closely with us to refine each prototype until perfection was achieved. The result was a series of prototypes that exceeded our expectations, enabling a seamless transition to the final product development phase.

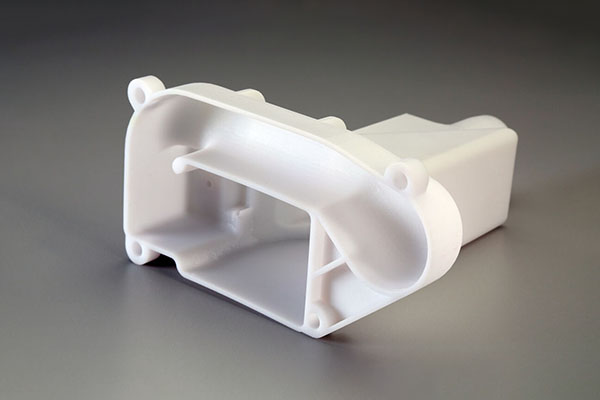

AeroSpace Dynamics’ partnership with NOWfab and their SLM 3D printing service was pivotal in overcoming our production hurdles. The complexity of our aerospace components required a level of precision and durability that only NOWfab could deliver. Their expertise in SLM technology transformed our approach to manufacturing, producing parts with the strength and precision needed for aerospace standards. Their proactive communication and adaptability to our project needs made them an indispensable part of our success.

Faced with stringent requirements and complex prototypes, their team not only met but exceeded our expectations. Their proficiency across both SLA and SLM printing technologies provided us with high-quality, reliable solutions crucial for our rapid development cycles. The NOWfab team’s commitment to understanding and addressing our specific challenges has made them more than a service provider; they are a partner in innovation. Their expertise in navigating and solving the toughest challenges is unmatched.

Join Us in Crafting Excellence Together