Injection Molding Service

Speed Your Path from Design to Production: NOWfab offers a streamlined solution for ordering premium injection molded parts. Fast-track your iterations, tests, and large-scale production with design uploads for DFM feedback and pricing within just one business day.

- ISO 9001 Certified

- Parts Delivered as Fast as 24 Hours

- Quality Without Compromise

Our Injection Molding Services

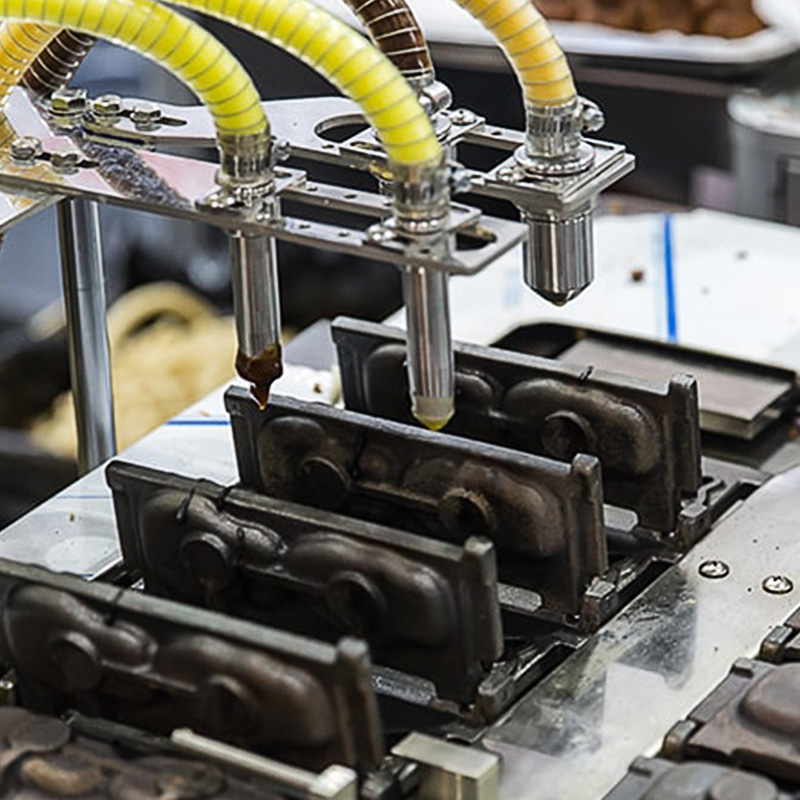

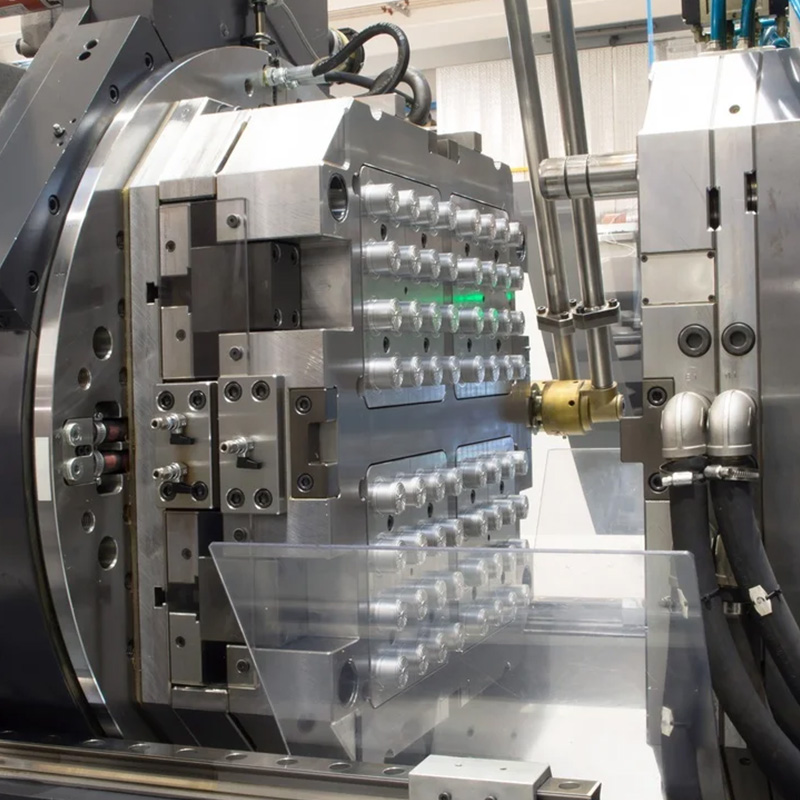

Injection Molding

Versatile production of durable, recyclable plastic parts.

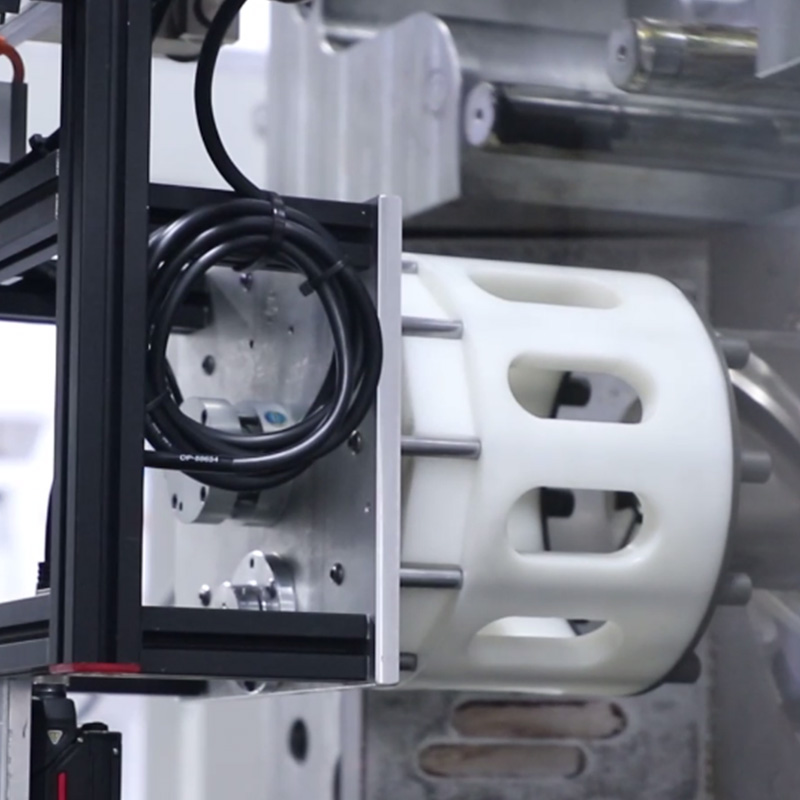

Overmolding

Enhancing parts with additional material layers for function and feel.

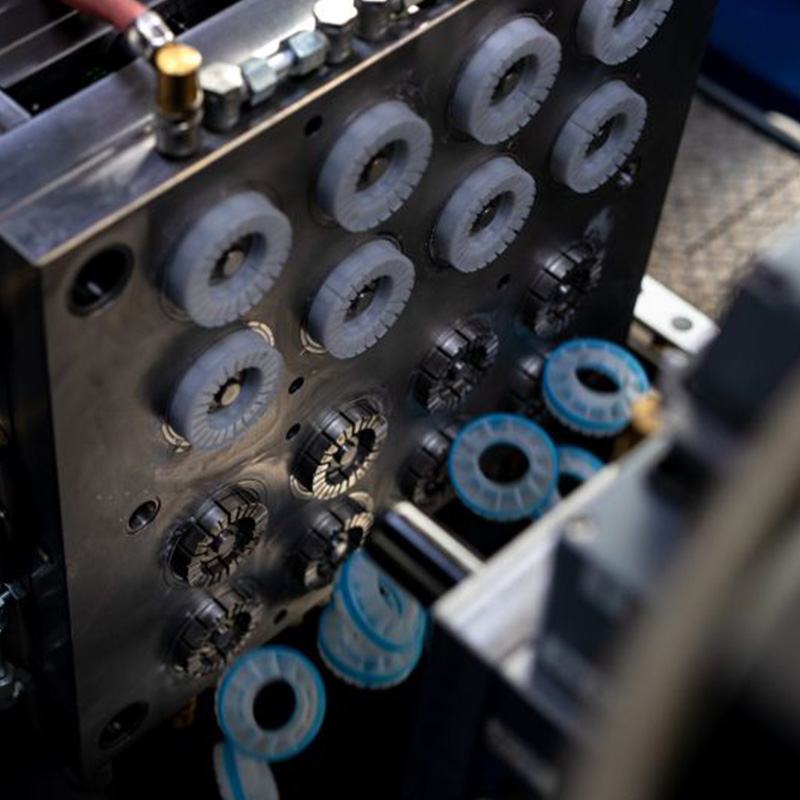

Insert Molding

Integrating metal parts with plastic for composite components.

Thermoset Molding

Creating heat-resistant components with irreversible curing.

Injection Molding Material

Injection Molding Parts Made by NOWfab

Explore Our Success Stories: Overcoming Customer Challenges

NOWfab revolutionized our product launch cycle with their exceptional injection molding service. Their fast delivery and DFM insights were instrumental in refining our designs, ensuring we hit the market with products of the highest quality. NOWfab is our go-to for reliability and excellence.

In the medical device industry, precision and quality are non-negotiable. NOWfab exceeded our expectations, delivering flawlessly molded parts that met all our stringent requirements. Their quick turnaround and proactive feedback system significantly boosted our development process. Highly recommended for any critical project.

Working with NOWfab has been a game-changer for our automotive component manufacturing. Their injection molding services provided not only high-quality parts but also rapid delivery times that kept our production schedule on track. The detailed DFM feedback helped us optimize our designs for better performance and cost-efficiency.

Injection Molding FAQs

1. What is the process for getting started with NOWfab Injection Molding services?

Starting with NOWfab's injection molding services is straightforward. Upload your design files on our platform, and receive Design for Manufacturability (DFM) feedback along with pricing within one business day.

2. How does NOWfab ensure the quality of injection molded parts?

Quality is at the core of NOWfab's services. We utilize state-of-the-art technology and rigorous quality control processes, from initial DFM feedback to final production, ensuring every part meets your specifications and our high standards.

3. Can NOWfab handle high-volume production orders?

Absolutely. NOWfab is equipped to handle high-volume production orders with the same level of precision and efficiency as prototype and small batch orders, ensuring scalability without compromising quality.

4. What is the typical lead time for injection molding projects with NOWfab?

Our lead times are competitive, with prototyping as fast as 1-2 weeks and production orders tailored to meet your project deadlines. Expedited services are available; please inquire for specifics.

5. Does NOWfab offer prototyping services for injection molded parts?

Sure, prototyping is a crucial part of our injection molding services. It allows you to test and refine designs before full-scale production, with rapid turnaround times to accelerate your development cycle.

6. How does NOWfab's Design for Manufacturability (DFM) feedback work?

Our DFM feedback is provided within one business day of design submission. Our experts analyze your designs to identify potential manufacturing issues, suggest optimizations for cost-efficiency and quality, and ensure manufacturability.

7.Can NOWfab support custom material requests for injection molding projects?

Yes, we can accommodate custom material requests. If you have specific material requirements for your project, our team will work with you to source or recommend alternatives that meet your specifications.

Come With Us on a Journey to Innovate Better and Faster