From Prototypes to Production: Mastering 3D Printing in Automotive Applications

- Release Date: April 18, 2024

From Prototypes to Production: Mastering 3D Printing in Automotive Applications

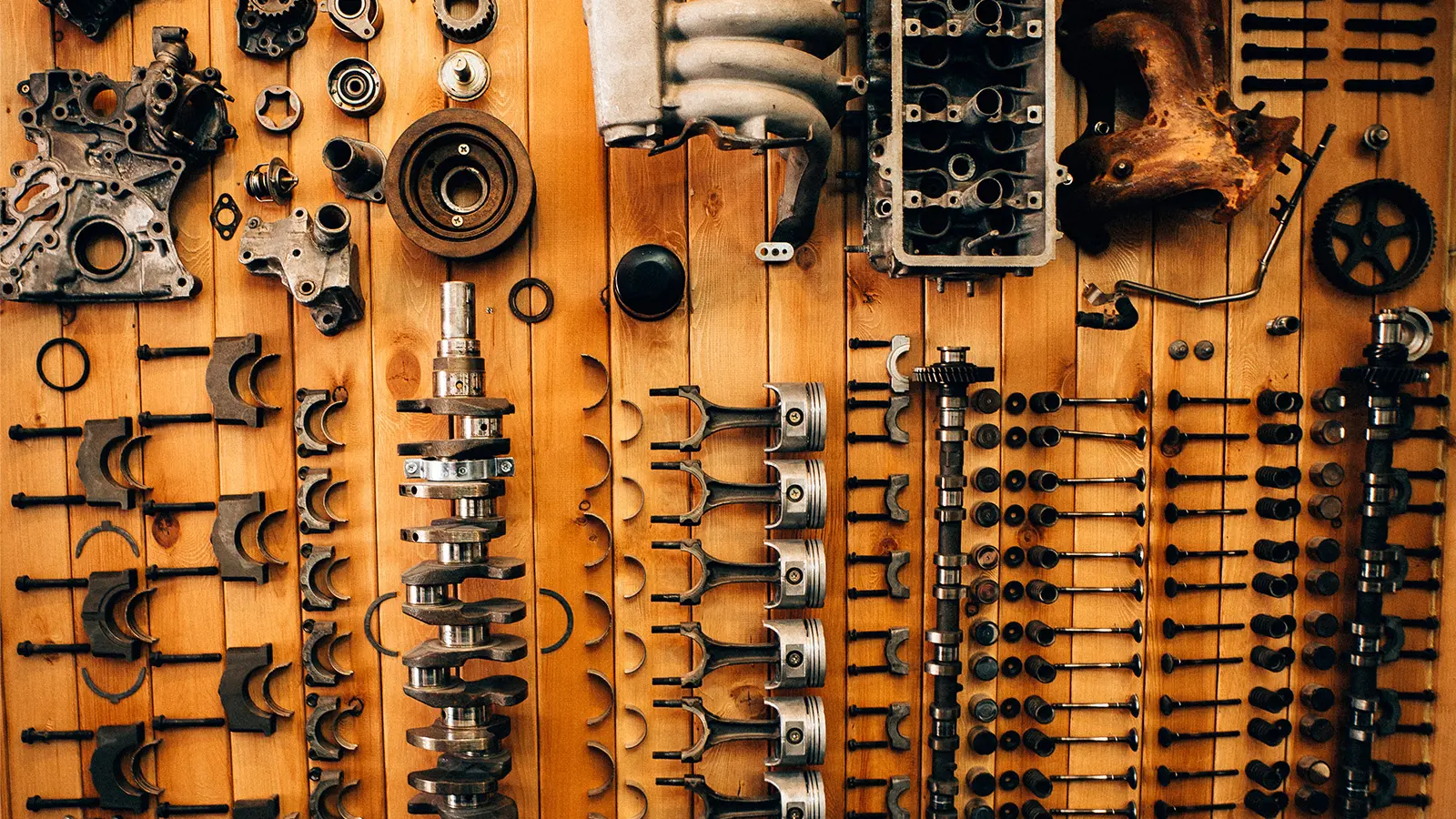

Imagine if the automotive industry had discovered the Philosopher’s Stone, a magical tool capable of transforming simple materials into precious automotive parts almost instantly. 3D printing plays this role, transmuting basic polymers and metals into complex components that are seamlessly integrated into modern vehicles, much like the alchemy of turning lead into gold. This transformative technology has rewritten the rules of car manufacturing, allowing design and production to dance in unprecedented harmony.

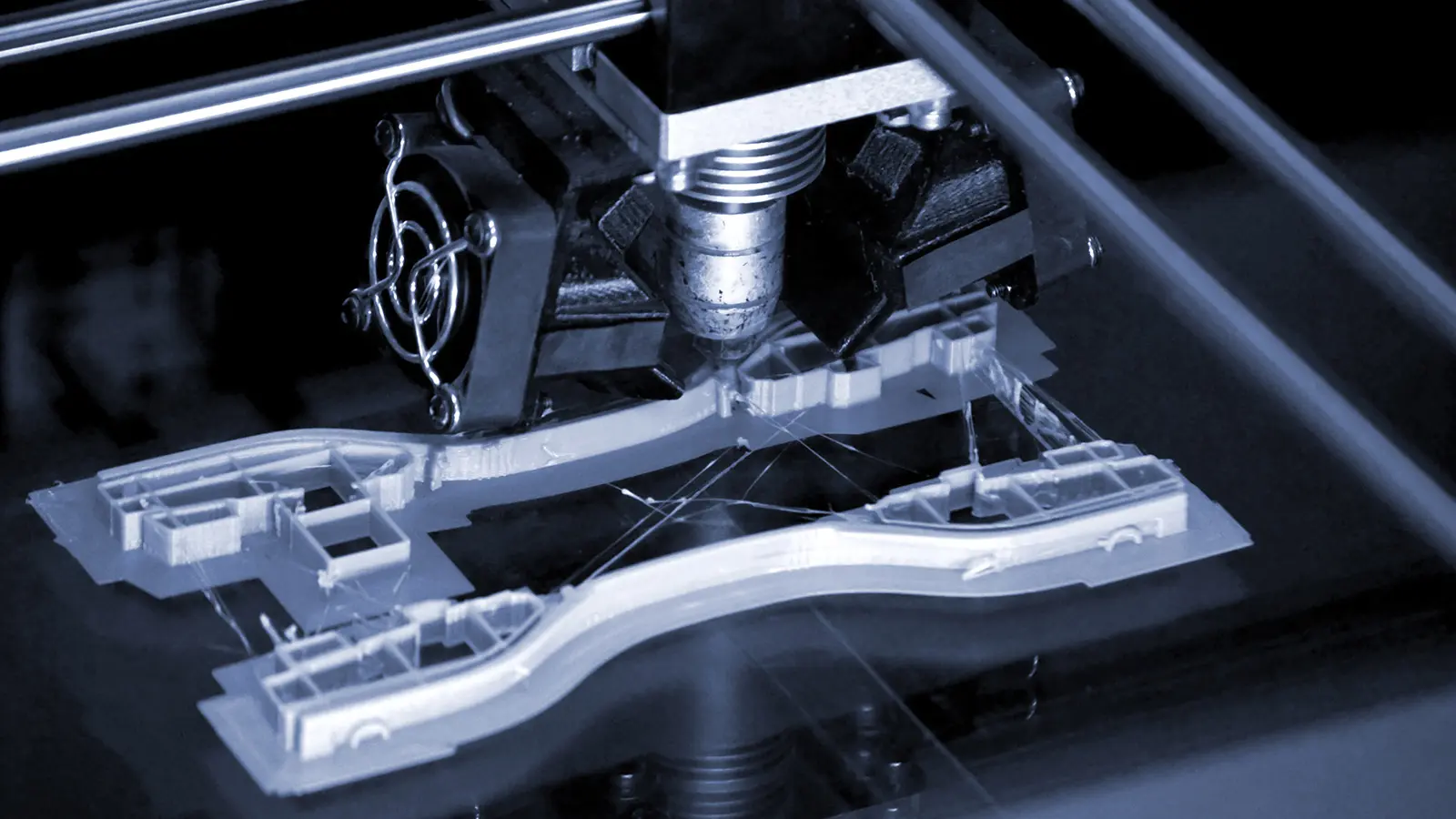

The introduction of 3D printing in automotive production is akin to a knight in shining armor, rescuing the industry from the high costs and slow pace of traditional manufacturing methods. Designers and engineers now wield the power of rapid prototyping, with ideas solidifying into reality as quickly as the thoughts themselves. This technology has dismantled the barriers of conventional manufacturing, permitting the adoption of flexible, innovative processes that shape raw elements with the precision of a sculptor.

This guide will take you through the enchanting realm of 3D printing in the automotive field, exploring how it breathes new life into raw materials to create lighter, stronger, and more efficient vehicles. As we embark on this transformative journey, we will discover how 3D printing continues to revolutionize the way cars are conceived and manufactured, heralding a future where automotive production is limited only by the bounds of imagination.

Fundamentals of 3D printing technology

Types for 3D Printing in Automotive Applications

3D printing, or additive manufacturing, offers a diverse array of techniques, each perfectly suited for different aspects of automotive production. Selective Laser Sintering (SLS), Fused Deposition Modeling (FDM), and Stereolithography (SLA) stand as the most popular technologies in the industry. These methods are chosen for their ability to produce durable and reliable parts, ranging from simple prototypes to complex load-bearing components.

Here are specific examples of how 3D Printing technologies, including Selective Laser Sintering (SLS), Fused Deposition Modeling (FDM), and Stereolithography (SLA), are applied in the automotive industry:

1. Selective Laser Sintering (SLS):

(1) Prototyping Engine Components: Automotive manufacturers employ SLS 3D Printing to produce prototypes of engine components such as intake manifolds, throttle bodies, and valve covers. These 3D Printing prototypes can be tested for fit, form, and function before mass production.

(2) Customized Interior Parts: SLS 3D Printing is also utilized to manufacture customized interior parts like dashboard panels, center console components, and door handles. These parts can be tailored to specific customer preferences or vehicle models, offering customization without the need for expensive tooling.

2. Fused Deposition Modeling (FDM):

(1) Tooling and Fixtures: Automotive assembly lines often require custom tooling and fixtures for tasks like assembly, inspection, and testing. FDM 3D Printing technology enables rapid production of these tools and fixtures at a fraction of the cost and time compared to traditional methods.

(2) Jigs and Prototypes for Manufacturing Processes: FDM 3D Printing is used to create jigs and prototypes for various manufacturing processes, such as welding, painting, and assembly. These 3D Printing aids help streamline production workflows and improve overall efficiency.

3. Stereolithography (SLA):

(1) Lightweight Prototype Parts: SLA 3D Printing is employed to fabricate lightweight prototype parts for automotive applications, such as brackets, mounts, and housings. These 3D Printing parts can be quickly iterated upon to meet design requirements and performance targets.

(2) Wind Tunnel Testing Models: SLA 3D Printing technology is utilized to produce accurate scale models of vehicles for wind tunnel testing. These 3D Printing models allow engineers to assess aerodynamic performance and make design improvements to enhance fuel efficiency and reduce drag.

Materials for 3D Printing in Automotive Applications

The choice of materials in 3D printing is pivotal in achieving the desired strength, flexibility, and durability of automotive parts. Thermoplastics such as ABS (Acrylonitrile Butadiene Styrene), PLA (Polylactic Acid), and advanced composites infused with carbon fiber or glass are commonly used. Each material brings distinct properties to the table, making the selection a crucial step in automotive design and manufacturing.

Leveraging the ubiquity of these materials in the 3D printing domain, a myriad of automotive components has been successfully manufactured, showcasing the adaptability and versatility of these substances for the automotive sector.

1. ABS (Acrylonitrile Butadiene Styrene):

(1) Interior Trim Components: Many interior trim components such as dashboard panels, door handles, and center console parts are made from ABS for 3D Printing. ABS offers good impact resistance and surface finish, making it suitable for visible parts within the vehicle cabin.

(2) Exterior Body Panels: Some automotive manufacturers use ABS in 3D Printing for producing exterior body panels, particularly in low-volume or specialty vehicles. ABS body panels are lightweight and can be easily molded into complex shapes.

2. PLA (Polylactic Acid):

(1) Prototyping Parts: PLA, known for its biodegradability, cost-effectiveness, and ease of 3D Printing, is commonly utilized for rapid prototyping of automotive components. A variety of part prototypes, including interior fittings, brackets, and housings, can be swiftly manufactured using PLA.

(2) Non-Structural Components: PLA is also suitable for non-structural components where mechanical strength requirements are not stringent, such as ducts, covers, and brackets in 3D Printing. Its biocompatibility and low toxicity make it appropriate for certain automotive applications.

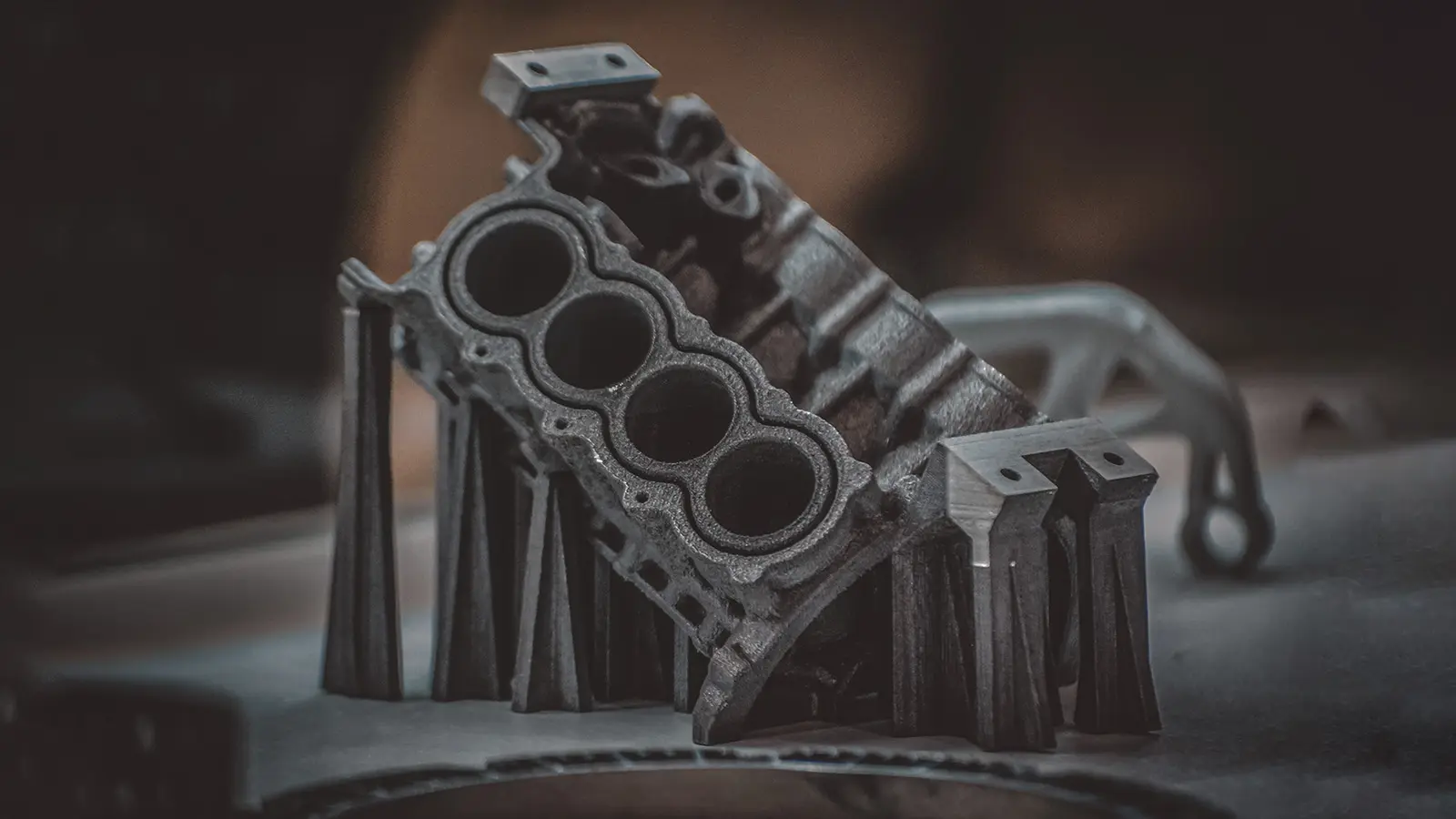

3. Advanced Composite Materials Reinforced with Carbon or Glass Fibers:

(1) Body Panels and Structural Parts: Advanced composite materials like Carbon Fiber Reinforced Polymers (CFRP) or Glass Fiber Reinforced Polymers (GFRP) are increasingly being used in automotive manufacturing for 3D Printing to create lightweight body panels and structural parts. These materials offer an excellent strength-to-weight ratio, enhancing performance and fuel efficiency.

(2) Suspension Components: Suspension parts such as control arms, springs, and stabilizer bars are produced using carbon or glass fiber composites in 3D Printing. These components benefit from the high strength and rigidity of composite materials, leading to improved handling and ride quality.

(3) Interior and Trim: Automotive manufacturers also employ carbon fiber composites for interior and trim applications in 3D Printing to enhance the vehicle’s aesthetic appeal. Carbon fiber trim pieces add a premium look and feel to the interior while also contributing to overall weight reduction.

Pivotal Advantages of 3D Printing in the Automotive Industry

Reducing Prototyping Costs and Enhancing Efficiency

3D printing has significantly reduced costs and development time, revolutionizing prototype development in the automotive industry. Traditional prototype manufacturing methods are not only expensive but also time-consuming, involving multiple stages of mold creation and adjustment. In contrast, 3D printing can quickly produce prototypes directly from digital designs, substantially cutting costs and time. A notable example is Ford Motor Company, which has integrated 3D printing technology to produce prototype parts for its various vehicles. This approach has allowed Ford to reduce prototype development time by 25%, significantly accelerating the product development cycle.

Mass Customization: Meeting Consumer Demands

The ability to customize automotive parts for both aesthetic and functional purposes is another significant advantage offered by 3D printing. This technology enables manufacturers to provide personalized options for their customers, something that was not possible due to the limitations of traditional manufacturing. For instance, BMW’s subsidiary, Mini, offers customers the ability to personalize features like dashboards and door handles through 3D printing, providing a unique touch that distinguishes their vehicles from others. This level of customization is becoming a key differentiator in the consumer market, enhancing customer satisfaction and loyalty.

Sustainability through Material Innovation and Waste Reduction

Sustainability is a major concern in the automotive industry, and 3D printing contributes significantly to eco-friendly efforts. The technology uses only the material necessary for the manufacture of parts, minimizing waste, which is a stark contrast to subtractive manufacturing methods that involve cutting from large blocks of material. Additionally, 3D printing can utilize new, lighter materials, reducing the overall weight of vehicles, thus improving fuel efficiency and reducing emissions. Audi has leveraged this technology to produce lighter automotive components, not only reducing the weight of their cars but also enhancing performance and minimizing the carbon footprint.

The Application of 3D Printing in the Automotive Industry

Redefining Prototyping: Accelerating Speed and Precision in Automotive Design

BMW, a frontrunner in the automotive industry, has consistently been at the vanguard of integrating 3D printing technology into its design and manufacturing processes. A quintessential example is their application of rapid prototyping to expedite the testing and refinement of new car designs.

Through the Industrialization and Digitalization of Additive Manufacturing (IDAM) project, BMW has successfully implemented fully automated 3D printed automotive production lines for metal Laser Powder Bed Fusion (LPBF). This showcases BMW’s commitment to leveraging 3D printing not only for prototyping but also for the production of complex components with high precision and performance.

The BMW Group has also been additively manufacturing metal and polymer parts, indicating their use of 3D printing in the production of both prototype and end-use parts. The dual application of 3D printing technology allows BMW to quickly create and test new designs, thereby enabling more efficient and cost-effective production processes in the automotive industry.

Furthermore, BMW’s new Additive Manufacturing Campus consolidates the production of prototypes and series parts, further emphasizing the use of 3D printing in the automotive design process. This centralized approach streamlines development, where rapid prototyping can swiftly lead to series production, thereby enhancing BMW’s competitive edge in the automotive industry.

In summary, BMW’s adoption of 3D printing technology for rapid prototyping is a testament to the transformative impact of this technology on the automotive industry. It enables faster design iterations, more efficient production, and ultimately, the delivery of innovative and high-quality vehicles to consumers.

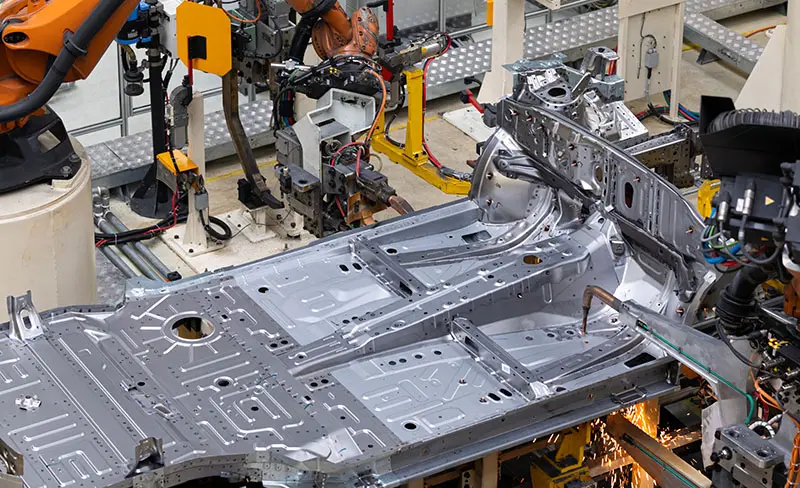

From Concept to the Road: Revolutionizing Production with 3D Printing

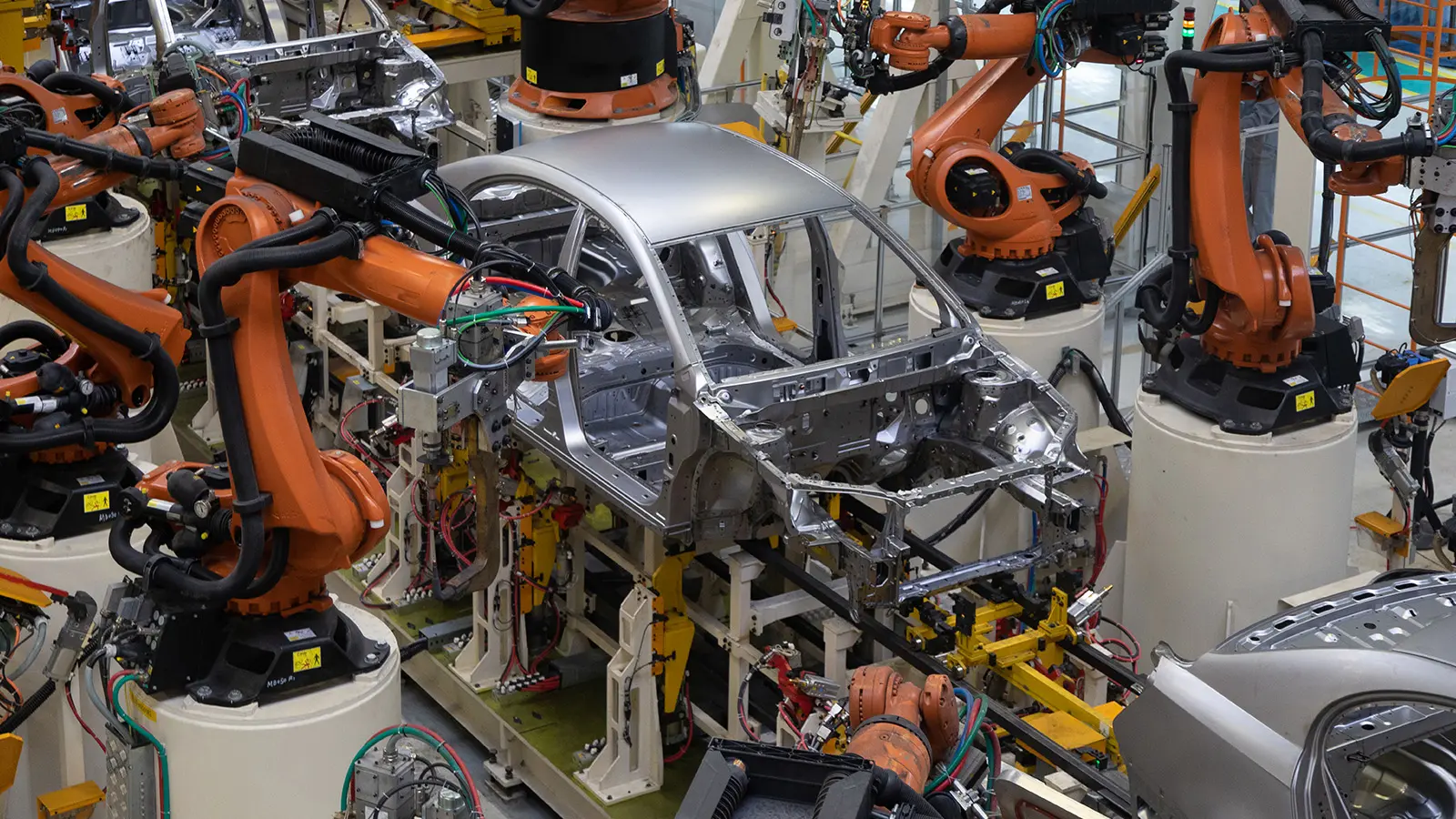

The advent of 3D printing is reshaping the manufacturing landscape by simplifying production methods that are not only more efficient but also economically viable. This technological innovation is reducing the industry’s traditional reliance on mass production models, paving the way for more agile and sustainable manufacturing practices.

General Motors utilizes 3D printing technology in its manufacturing facilities to produce tools, fixtures, clamps, and prototypes. These 3D printed components play a crucial role in enhancing efficiency, reducing lead times, and enabling design innovation in automotive production.

1. Tools and Fixtures:

General Motors uses 3D printing to manufacture custom tools and fixtures for its production lines. This includes assembly jigs, inspection gauges, ergonomic aids, and forming tools. By 3D printing these tools, General Motors can rapidly iterate designs, customize solutions for specific tasks, and reduce the time and cost associated with traditional mold production methods.

2. Prototyping:

General Motors employs 3D printing to create rapid prototypes of vehicle parts, allowing engineers to test and validate designs before committing to mass production. By producing prototypes in-house using 3D printing technology, General Motors accelerates the product development cycle, identifies design flaws early on, and reduces the need for costly tooling changes later in the process.

3. End-Use Parts:

In addition to tooling and prototype design, General Motors also explores the use of 3D printing to manufacture end-use parts that are integrated directly into its vehicles. Complex components, such as interior parts, brackets, and sensor housings, can be 3D printed using advanced materials that meet the required standards for performance and durability.

At General Motors’ production facilities, engineers use 3D printing to produce custom assembly jigs for aligning and installing electronic components in vehicle dashboard assemblies. These 3D-printed jigs feature complex geometries and precise tolerances, tailored to specific assembly requirements, thus enhancing the efficiency and accuracy of the production line.

By integrating 3D printing technology into its production lines, General Motors has optimized manufacturing processes, reduced costs, and driven innovation across its entire range of vehicles, ultimately delivering higher-quality products to customers.

Customization at the Speed of Thought: Personalized Driving Experiences

The automotive industry is witnessing a revolution in customer-centric design, with 3D printing at the forefront. Brands like Porsche are tapping into the technology to offer a new dimension of personalization that resonates with individual drivers’ tastes and needs. This approach is not just about aesthetics; it’s about crafting a driving experience that is as unique as the drivers themselves.

Porsche exemplifies this trend by employing 3D printing to produce bespoke auto components. With state-of-the-art scanning and design processes, they can tailor intricate styling elements and materials to not only enhance visual appeal but also to refine ergonomics for unparalleled comfort. This level of customization is redefining luxury in the automotive market, shifting the paradigm from mass-produced uniformity to individually-crafted excellence. It’s an era where every curve and contour of a vehicle’s interior and exterior can be meticulously designed and produced to match the owner’s flair—ushering in a future where the car is not just a mode of transport, but a reflection of the driver’s identity.

Starting with the customization process, Porsche allows 3D printing to empower a personalized driving experience.

1. Body Scanning: When a customer opts for a personalized seat, Porsche conducts a detailed body scan to capture the precise contours and dimensions of the individual’s physique.

2. Design Optimization: Utilizing the scan data, Porsche engineers design an ergonomically optimized seat that provides the best support and comfort for the client. This includes adjusting the seat contours, lumbar support, and padding thickness to suit the individual’s body shape and preferences.

3. 3D Printing: Porsche employs state-of-the-art 3D printing technology to manufacture the customized seat components. High-resolution 3D printers produce complex lattice structures and intricate geometries, optimizing weight, strength, and comfort.

4. Material Selection: Porsche offers a range of materials for the seat components, including lightweight polymers, carbon fiber-reinforced composites, and specialized cushioning materials. Customers can choose materials based on their desired balance of comfort, performance, and aesthetic appeal.

A Porsche customer opts for the customized seat option when ordering a new sports car. After undergoing a body scan at a Porsche dealership, the customer selects their preferred seat design, material, and color scheme. Porsche then utilizes 3D printing technology to manufacture the customized seat components, ensuring a perfect fit and optimal comfort for the customer.

By incorporating 3D printing into its customization process, Porsche demonstrates its commitment to offering personalized solutions that enhance both comfort and performance for its discerning clientele.

Conclusion

3D printing is set to revolutionize automotive manufacturing further, making it an exciting time for industry stakeholders to leverage this technology. At NOWfab.com, we are committed to providing cutting-edge solutions that meet the needs of modern manufacturers and set new standards in automotive production.

Explore more about our 3D printing capabilities and discover how we can help transform your automotive production by visiting our website and getting in touch with our experts. Together, let’s drive the future of automotive manufacturing.

Try NOWfab Now!

All information and uploads are secure and confidential.

Latest Blog Posts

Stay at the forefront of industry innovation by reading our latest blog post.