Comparing Die Casting and Compression Molding: Definitions, Characteristics and Applications

- Release Date: April 26, 2024

Comparing Die Casting and Compression Molding: Definitions, Characteristics and Applications

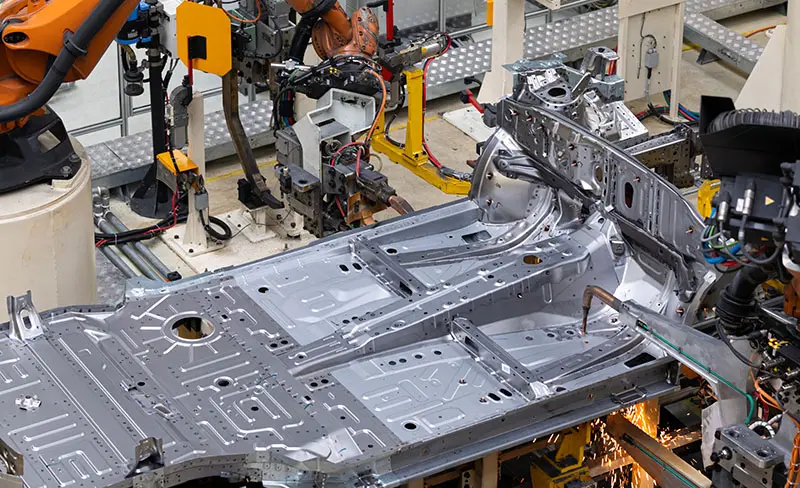

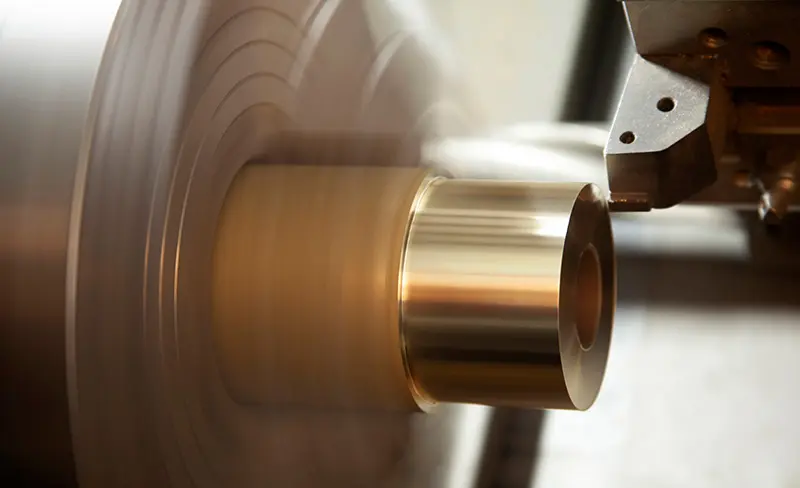

Metalworking encompasses a vast array of processes crucial to modern manufacturing. Die casting and compression molding stand out as key techniques, each offering unique advantages in producing metal components. Die casting involves injecting molten metal into a mold cavity under high pressure, ideal for intricate shapes and high-volume production. In contrast, compression molding compresses preheated material in a mold cavity, suitable for complex geometries and composite materials. Understanding these processes is essential for optimizing production efficiency and achieving the desired quality in metal component manufacturing.

Die Casting

Definition and Process of Die Casting

Die casting is a metalworking process that involves melting metal and injecting it into a steel mold, known as a die, under high pressure. The molten metal fills the cavity of the die, solidifying rapidly to form the desired shape of the final product. This method allows for the production of complex shapes with excellent dimensional accuracy and surface finish. Once cooled, the die is opened, and the finished part is ejected. Die casting is widely used in industries such as automotive, aerospace, and electronics for manufacturing a variety of components with high efficiency and precision.

Characteristics of Die Casting

1. High-Pressure Operation

High pressure in die casting ensures thorough filling of the mold cavity, minimizing porosity and achieving precise detail in the final product. This pressure also helps in reducing shrinkage and improving material density, resulting in parts with excellent mechanical properties and dimensional accuracy.

2. Rapid Filling of Cavity

The speed of filling the mold cavity in die casting significantly impacts the quality and properties of the cast part. Faster filling rates can reduce defects like porosity and ensure uniform material distribution, leading to parts with superior mechanical properties and dimensional accuracy.

3. High Precision and Low Surface Roughness

Die casting achieves high precision and a smooth surface finish through the use of a precisely machined steel mold, high-pressure injection of molten metal, and rapid solidification. This process minimizes defects and allows for intricate details in the final product.

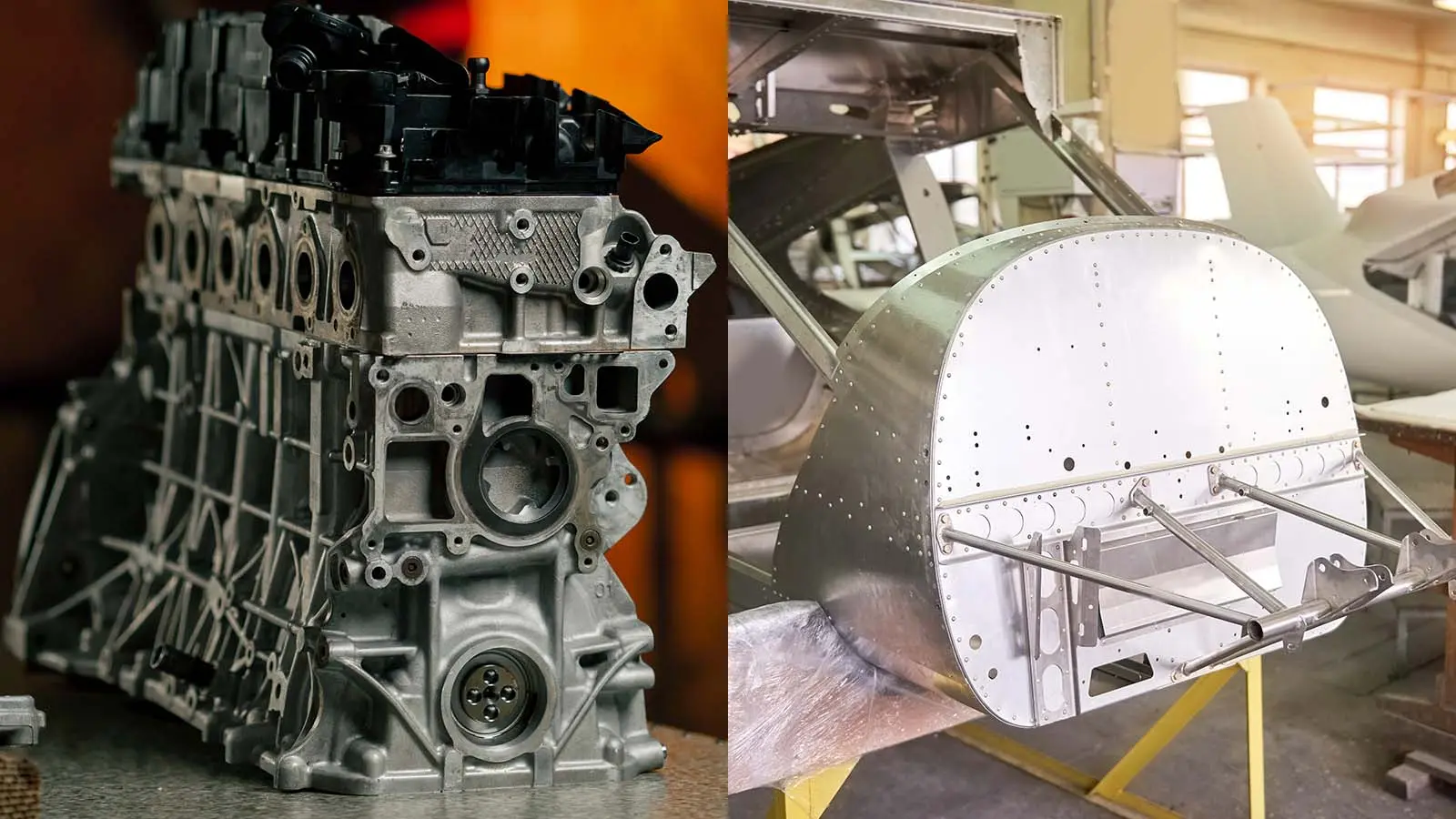

Applications of Die Casting: Mass Production Examples

Die casting is extensively utilized in various industries for mass production of components requiring high precision and complex geometries. In the automotive sector, it’s used for manufacturing engine parts, transmission components, and structural elements. Additionally, electronic industries employ die casting for producing housings, enclosures, and heat sinks for electronic devices. Other applications include aerospace components, household appliances, and hardware fittings. The versatility and efficiency of die casting make it a preferred choice for producing high-quality parts in industries where precision, durability, and cost-effectiveness are paramount.

Compression Molding

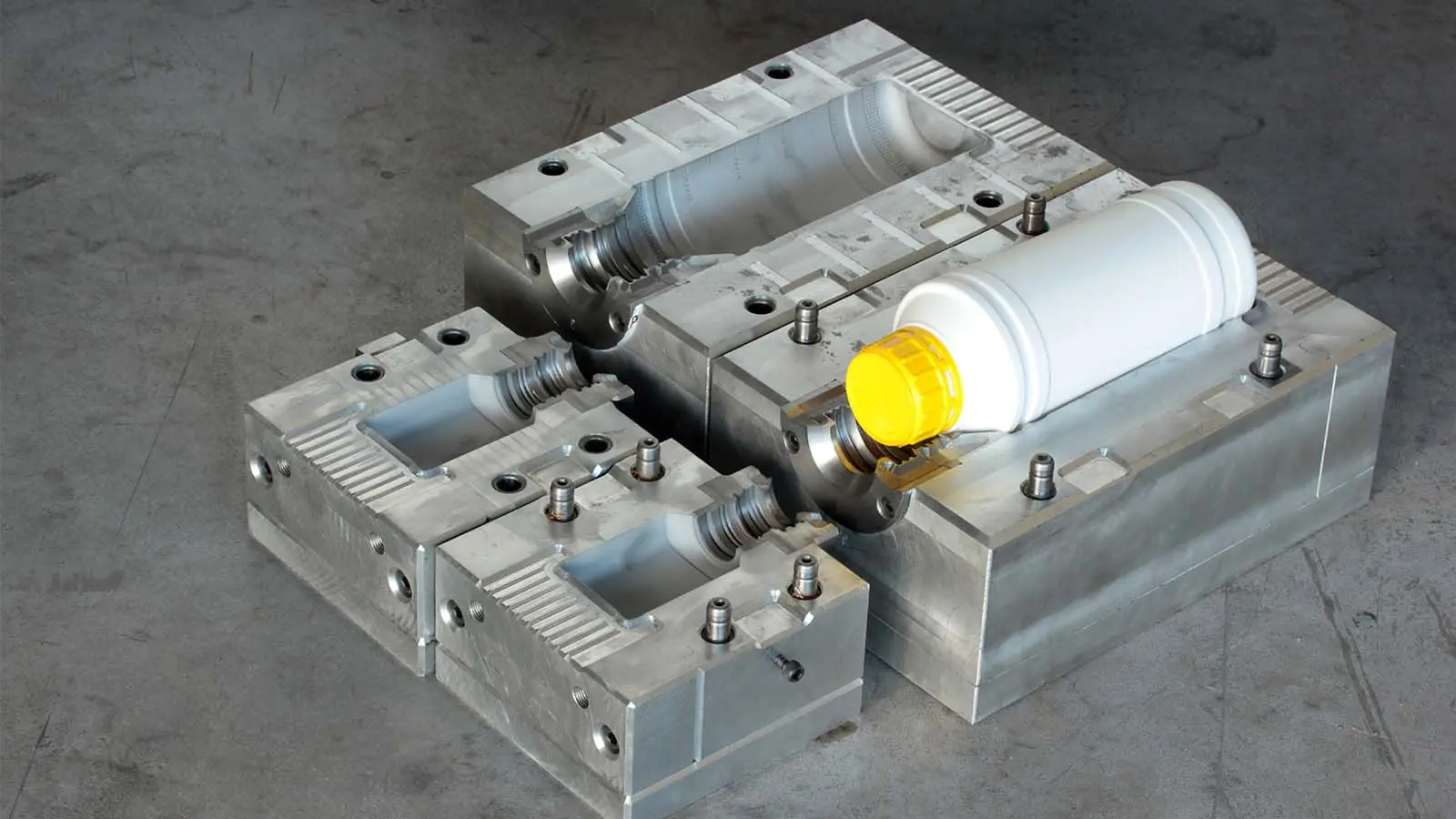

Definition and Process of Compression Molding

Compression molding is a manufacturing process used to shape materials into desired forms by applying heat and pressure. In compression molding, a pre-measured amount of material is placed into a heated mold cavity. The mold is then closed, and pressure is applied to compress the material, forcing it to conform to the shape of the mold. Heat and pressure are maintained until the material cures or solidifies. Compression molding is commonly used for producing parts with complex geometries, composite materials, and large production runs due to its efficiency and versatility in shaping various materials like plastics, rubber, and composites.

Characteristics of Compression Molding

1. Material Compaction without High Pressure

Compression molding compacts materials by applying moderate pressure to a heated mold cavity, forcing the material to conform to the shape of the mold. Unlike die casting, which uses high pressure, compression molding achieves consolidation through controlled compression and heat without extreme pressures.

2. Non-Metal Material Processing

Common non-metal materials processed through compression molding include thermosetting plastics like phenolic resins, thermoplastics like polyethylene and polypropylene, and composite materials like fiberglass and carbon fiber. Compression molding is versatile, accommodating various materials for a wide range of applications in industries such as automotive, aerospace, and consumer goods.

Applications of Compression Molding: Mainly for Non-Metal Materials

Compression molding is widely utilized in the plastics industry for various applications. One example is the production of composite parts for automotive components, such as exterior panels and interior trim, where compression molding is used to create lightweight, durable parts with intricate designs. Another example is in the manufacturing of electrical insulation components, like circuit breaker housings and insulating bushings, where compression molding produces parts with excellent electrical properties and dimensional stability. Additionally, compression molding is employed in the production of kitchenware and household goods, such as melamine dinnerware and plastic containers, providing cost-effective solutions for mass-producing items with consistent quality and aesthetics. These examples illustrate the versatility and effectiveness of compression molding in meeting diverse manufacturing needs within the plastics industry.

Comparative advantages of die casting and compression

Die casting and compression molding offer unique advantages in manufacturing. Die casting provides high precision and complex shapes with tight tolerances, making it ideal for producing intricate components like automotive engine parts. For example, in the automotive industry, die casting is commonly used to manufacture engine blocks due to its ability to produce intricate designs with excellent dimensional accuracy.

On the other hand, compression molding excels in producing large, high-strength parts with minimal waste and cost-effectiveness. A real-world application of compression molding can be seen in the production of composite materials for aerospace components. For instance, compression molding is utilized to manufacture aircraft panels and structural components, where lightweight and durable materials are crucial for enhancing fuel efficiency and performance.

Both die casting and compression molding offer unique advantages tailored to specific manufacturing needs, whether it’s precision and complexity in die casting or cost-effectiveness and strength in compression molding. Understanding the differences between these processes allows manufacturers to choose the most suitable method for their production requirements.

Conclusion

Die casting and compression molding are both manufacturing techniques used to shape materials into desired forms, but they differ in key aspects. Die casting involves injecting molten metal into a steel mold under high pressure, ideal for high-volume production of complex metal parts. In contrast, compression molding compacts materials, typically thermosetting plastics, in a heated mold cavity under moderate pressure, suitable for producing parts with intricate designs and composite materials. While die casting offers high precision and surface finish for metal components, compression molding provides versatility and cost-effectiveness for plastic and composite parts.

Try NOWfab Now!

All information and uploads are secure and confidential.

Latest Blog Posts

Stay at the forefront of industry innovation by reading our latest blog post.